PA3200GF

Glass-reinforced polyamide provides excellent surface quality and precise details.

Glass reinforced polyamide. The raw material is polyamide (PA12) mixed with small glass beads. The beads strengthen the resulting parts and increases the stiffness, abrasion resistance, and temperature resistance. This also gives the parts a slightly smoother surface quality. Typical applications include fully functional end products and visual or functional prototypes. PA3200GF is commonly used for enclosing hot environments and for applications requiring stiffness.

SURFACE TREATMENT

The most common surface treatment is submersion dyeing (available in all basic colors). With submersion the surface becomes smooth and the overall thickness does not change as much as compared to painting. A smooth surface quality resembling injection molded parts can be reached with vibration polishing.

3D Printing Technique: Selective Laser Sintering (SLS)

Build chamber/max size: 320 mm x 320 mm x 600 mm

Layer thickness: 120 um

Dimensional accuracy: ± 0,25mm + ± 0,1mm/100mm

Read more:

> About Selective Laser Sintering

> Design Guidelines for Selective Laser Sintering

Mechanical properties

Wall thickness

The recommended wall thickness is 1 mm. Structures smaller than this are very fragile and may not withstand the post processing stage where the excess powder is removed.

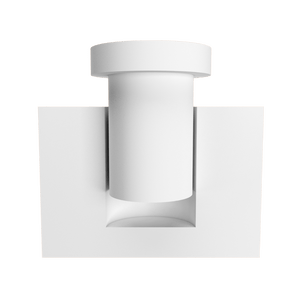

Clearance

The recommended clearance when constructing complex functional structures such as joints is 0.5 mm. In the production phase some powder stays between the parts and must be removed after finishing. If the clearance is too small the powder will compress and possibly even partially melt making it difficult to remove the parts.

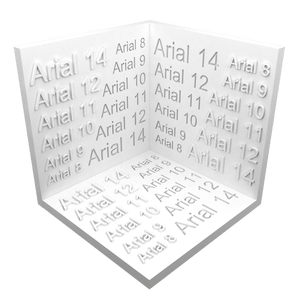

Inside and outside font labels

Inside and outside texts and labels are possible to print depending on the font size, depth/hight of the text and the orientation when printing. Consult our experts for more information.

Warping

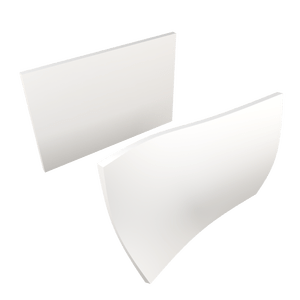

Large thin areas may warp during cooling process. The warping effect is minimised with good design and production management.