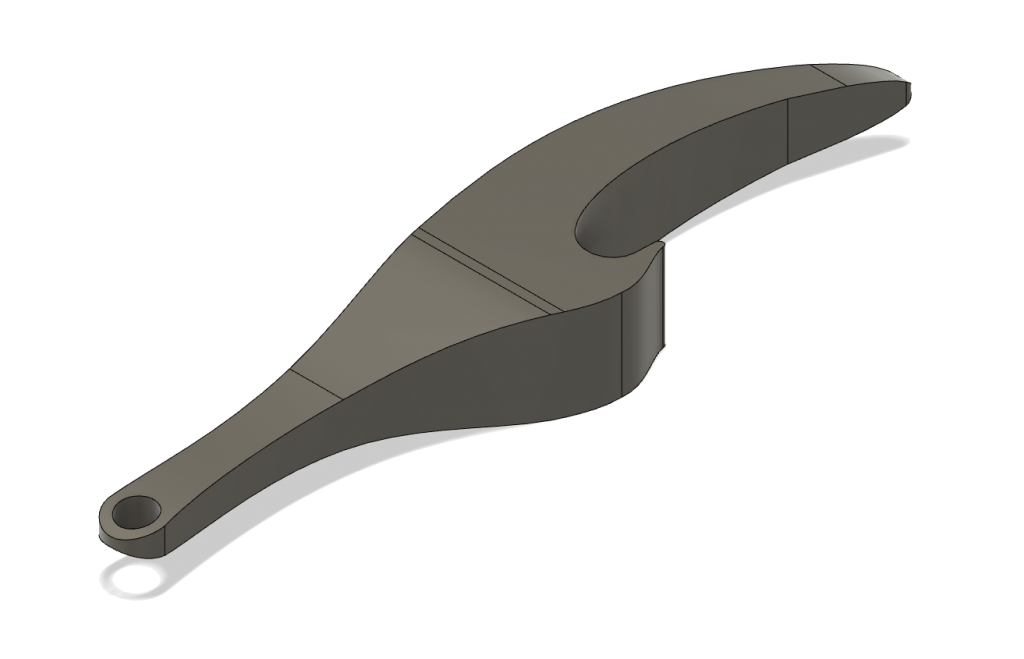

Design for additive – Self supporting geometry

“Opener” is a simple example product for applying topology optimisation (TO) for 3D printed metal parts. The raw material is used only where it’s actually needed based to the “Opener’s” mechanical requirements. Topology optimisation is a method to optimise the parts structures indicating the areas where mass can be reduced and where it’s needed due to mechanical stress.

To achieve good results with topology optimisation you’ll need a suitable software and a proper designer who knows how to set the correct conditions for a given product. Additive manufacturing has many design advantages compared to conventional subtractive manufacturing. Lighter and improved structures, complex geometries, and intricate shapes are just some of the perks. 3D printing opens new possibilities for product design bringing more freedom and options to the table as well as shorter design-to-manufacturing cycle. Adding quality topology optimisation the need for raw material can be trimmed down substantially lowering the overall costs significantly especially for products and spare parts with smaller production series.