3D Printing in Motorsport: To Progress, One Must Take Risks

The Heinonen Drift Team’s car featured a new 3D-printed intake manifold in the first race of the season 2024. Drifting cars possess more power than Formula 1 cars, and their components must endure extreme conditions. With 3D printing, custom parts can be created to help achieve better results.

The Drift Masters (DM) 2024 season consisted of six rounds, including both new tracks and classics.

One of the most anticipated events the year was the third round of the Drift Masters European Championship, held at PowerPark in Kauhava, Finland. This was the second time competitors visited Finland, following the success of the last season’s events. The track was challenging, and Finnish fans brought an incredible atmosphere.

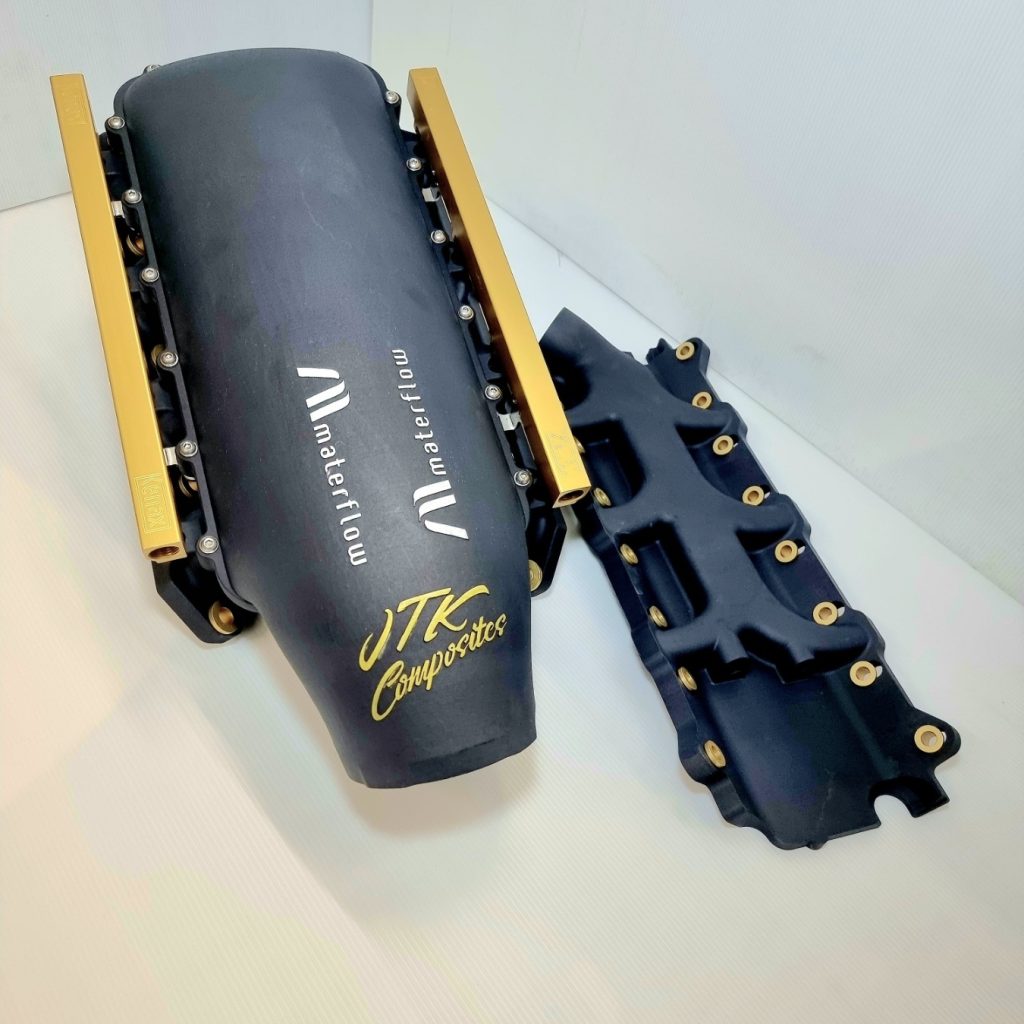

The Drift Masters season kicked off in Valencia, Spain, at Circuit Ricardo Tormo, from May 10–12. The Heinonen Drift Team impressively secured second place in the competition, with their car equipped with a new 3D-printed intake manifold. The manifold was produced using Materflow Oy’s highly durable plastic material, capable of performing under extreme conditions.

Valencia’s track is best known for MotoGP™ races and F1 testing. Drifting cars, with more power than Formula 1 vehicles, demand components that can withstand extreme stresses. 3D printing enables the creation of fully customized parts that enhance performance.

“Lauri Heinonen’s drift team needed to reduce the car’s weight. They asked if it was possible to create a lighter and more efficient intake manifold. The previous one was made of aluminum, so we began exploring suitable plastic materials,” says Jarno Kauppila from JTK Composites Oy, explaining the product development process.

Materflow Oy, specializing in industrial 3D printing of metal and plastic products, printed the intake manifold using PA12, a technical plastic designed for high-performance products and extreme conditions.

“For us, PA12 is probably our most commonly used plastic material—our bread and butter,” jokes Sami Mattila from Materflow.

Motorsport Is Continuous Development

“This was a completely new and experimental project for us, almost NASA-level work,” said Lauri Heinonen about the 3D-printed intake manifold. “But to grow, you need to take some risks.”

Drifting is a thrilling motorsport where drivers showcase control over their vehicles on varying tracks. Car optimization is a constant development process. The Heinonen Drift Team took a calculated risk in Valencia’s season opener with a new intake manifold.

“We achieved better airflow, increasing power, especially at lower RPMs,” explained Jarno Kauppila. A plastic manifold also prevents heat transfer from the engine, improving efficiency.

Materflow Oy specializes in industrial 3D printing, enabling complex designs unattainable with traditional methods. For this project, PA12 plastic was chosen for its durability and lightweight properties, contributing to the car’s 178 kg weight reduction.

“Custom-designed parts are often only feasible through 3D printing,” concluded Sami Mattila.