Design for additive – Flow channels

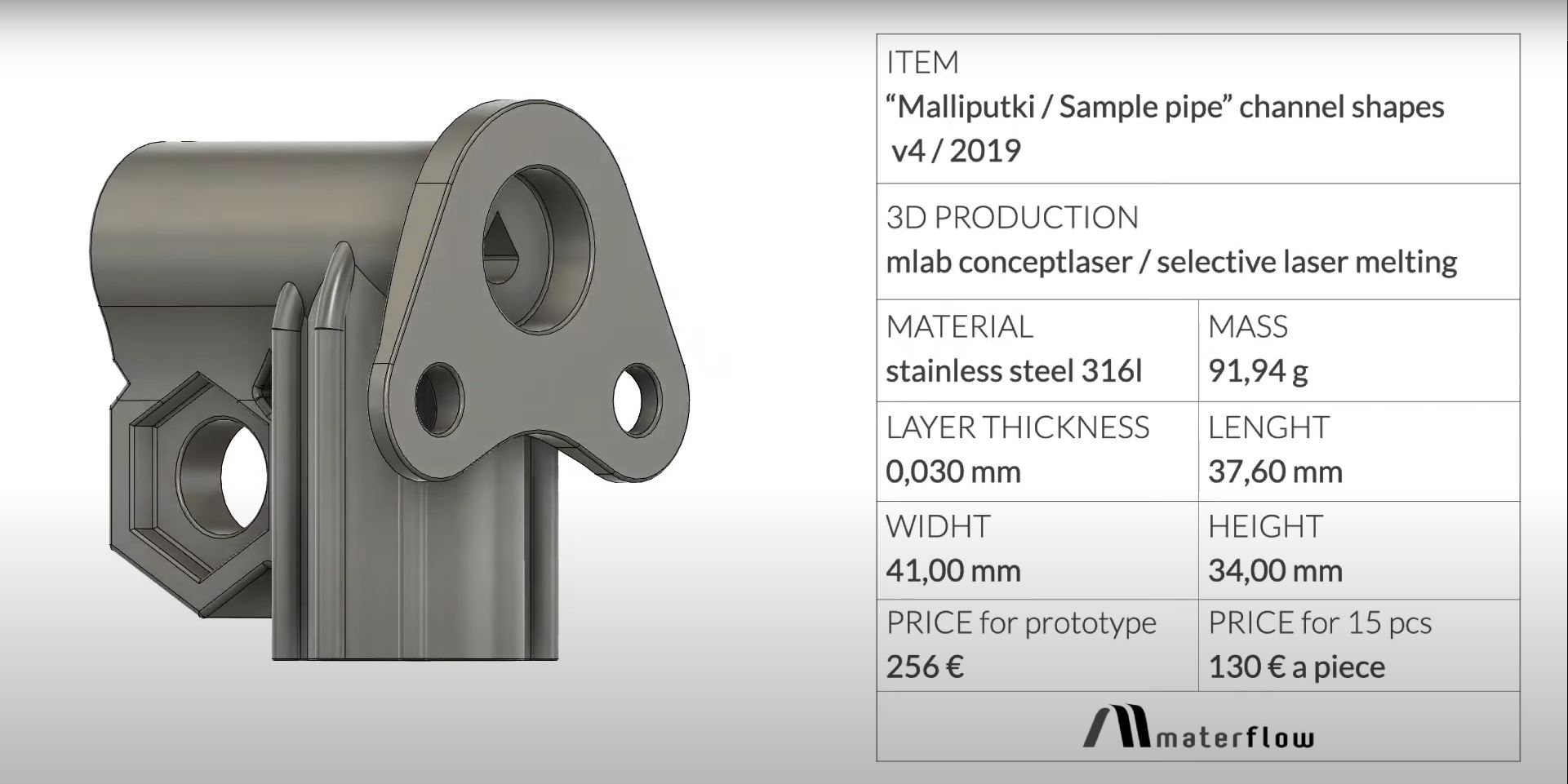

When 3D printing metal parts one of the most important aspects of the process is the parts design and the support structures required for printing, especially with flow channels and holes. To achieve faster production runs and better surface quality the amount of supports can be reduced with good design. The channels and holes should have a self-supporting shape since the supports can be difficult or impossible to remove in post-processing. Some shapes such as the drop or diamond seen in the video do not require supports at all. Another way to reduce supports is orientation i.e. the position/angle the part will be printed in.

Read more about the design guidelines for metal printing

Recommended Posts